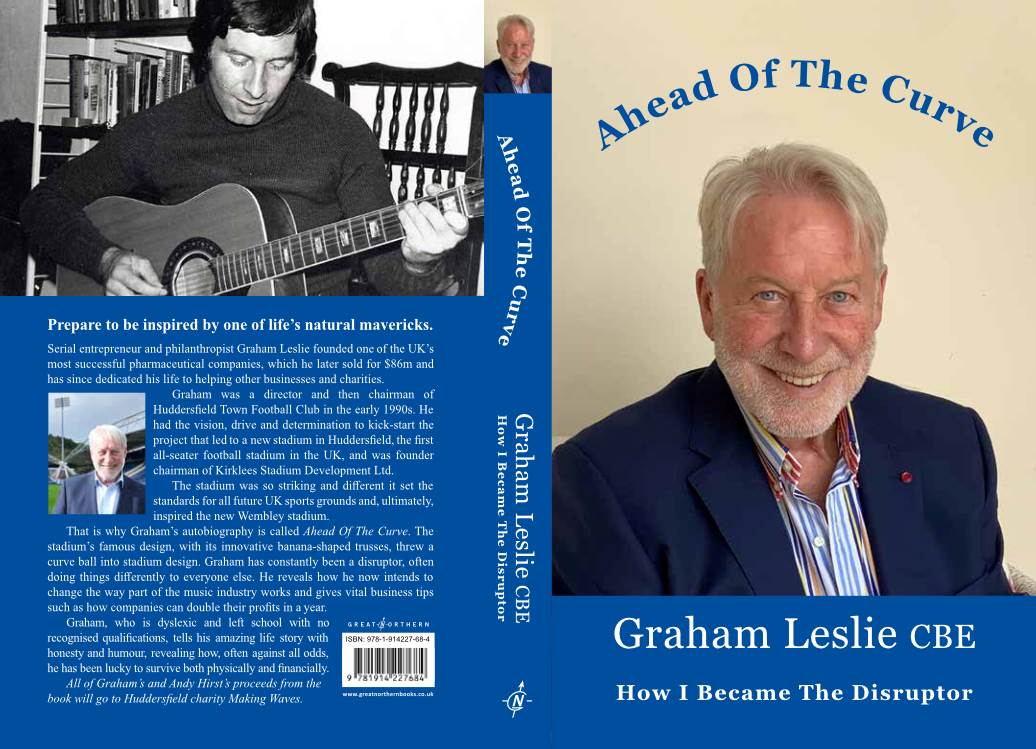

Serial Yorkshire entrepreneur and philanthropist Prof Graham Leslie CBE – who was the driving force behind building the John Smith’s Stadium – has written a revealing autobiography and Huddersfield Hub has an exclusive first serialisation of it.

Graham was Huddersfield Town chairman in the early 1990s and had the vision and determination for Huddersfield to have the first all-seater football and rugby stadium in Europe – one which would be a trailblazer for the rest to follow.

He founded one of the UK’s most successful pharmaceutical companies, Galpharm – which went on to sponsor the stadium – and Graham later sold his business and has since dedicated his life to helping other businesses and charities.

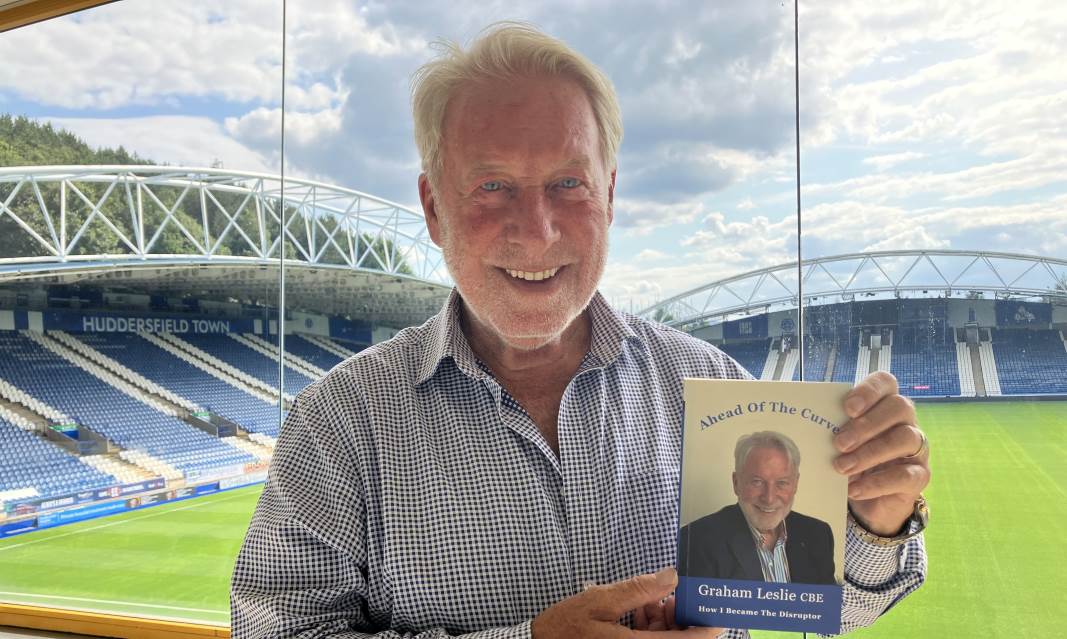

Graham’s book, which marks 30 years since the first match at the ‘new’ stadium in 1994, is called Ahead Of The Curve and will, fittingly, be launched in the Terriers Together suite at the stadium on Friday, July 26, at 10.30am and anyone is welcome to attend.

Town legends Andy Booth, Peter Jackson, Kieran O’Regan and Chris Hutchings will be there and will sign copies of the book along with Graham.

Graham Leslie (left) with David Taylor and Peter Jackson. Image by: SEAN DOYLE

Here’s what the book reveals about the day Galpharm revolutionised the pharmaceutical world forever.

We were lifted into the Premier League of pharmaceuticals one Friday afternoon in June 1995 – the day we proved to the Medicines Control Agency that our generic ibuprofen could be sold in supermarkets and shops rather than only in pharmacies. Up to then ibuprofen was a big pink tablet on prescription and sold by Nurofen but we turned it into a sugar-coated white tablet.

The MCA had to be sure the medicine would benefit the patient and pass efficacy and safety standards – basically that it worked and was completely safe. Data was collected from around the world as well as the UK.

It was the culmination of two years of research, development and thinking differently. For instance, a powerful dose of Nurofen at 400mg could only go through on prescription via the GPs. The Nurofen 200mg were on sale only in pharmacies but at a high cost.

But if the Galpharm tablets were only 200mg they could go over the counter so we used that to switch to a general sales list making it available everywhere.

By reducing the ibuprofen pack size to 16 we were allowed to sell it anywhere – the first company in Europe to move a molecule from the legal status of only being sold in pharmacies to be sold in grocers which included the big supermarkets.

We received a fax at our Brighouse headquarters that Friday afternoon and partied hard all weekend as nobody but ourselves fully grasped exactly what we’d achieved and what this moment meant for Galpharm. It was our Holy Grail and from then on we were known as the buccaneers of the pharma industry by launching affordable medicines for everyone.

The next few weeks needed shrouding in secrecy so we would shock the pharmaceutical world when we were ready to launch. We closed our chosen supplier, Sussex Pharmaceuticals, for six weeks while the packaging was printed to say Galpharm’s ibuprofen had general sales list status.

We knew no competitor would be able to catch us up for at least a couple of years.

From that day on we became instant major players. Our ibuprofen sold for 49p compared to the big name brands in the chemists which were £2.19, reaping them vast profits.

The retailers couldn’t believe it – at first they thought selling ibuprofen in shops was illegal – but we could assure them it was now perfectly legal and would provide them with their own brands. It opened a whole new sector for them and, instead of us trying to sell to them, they were suddenly coming to us.

Up to this point analgesics such as ibuprofen had only been available in pharmacies and the big manufacturers had become complacent with their market domination.

We’d suddenly opened up a whole new retail world for retailers … and they loved it. After all, there was no incentive at all for the big brands to do own brands for supermarkets as they’d be cutting their own profit margins.

We also quickly realised how much we were saving the NHS which we reckoned to be around £400m a year through savings on prescriptions of ibuprofen alone with people being able to buy it in supermarkets and other general grocery outlets rather than just at pharmacies.

The way was clear for Galpharm to forge ahead with that full speedboat mentality that served us so well.

We didn’t just provide the supermarkets with their own brand medicines, we also offered to sort out their marketing and packaging designs as part of the deal which was often incentive enough for them to sign contracts with us for three years. This meant the factories we used would know they’d have continual orders and secure futures.

Demand grew at such a phenomenal rate we needed more manufacturers on board and so looked beyond the UK.

We learned there were companies in India manufacturing for some of the UK brands so searched there … and found exactly what we were looking for.

Although, incredibly, there were more than 30,000 generic pharmaceutical manufacturers in India, only around 30 were equipped to meet the UK standards and we put our own Galpharm staff into those we chose to ensure they were meeting both the UK and European compliance and standards. Inspectors from the Medicines Control Agency also went over there to check them out.

Manufacturing costs were so much more economical that by the time I sold Galpharm almost all our medicines were being made in India and we never had a formal supply contract with the factories detailing terms and conditions for buying and delivering the products.

I’ve always thought that if someone gets a supply contract out of a drawer then it’s the beginning of the end of that business relationship as the trust has slipped.

If they ever mentioned concerns over whether they’d be paid then I’d tell them that if we didn’t pay them then don’t ship the goods, it’s as simple as that. Also, I’d get fined by the retailers for leaving them with empty shelves – they relied totally on us to provide their own brand products – so there was every incentive for all of us to stick to our agreement.

Our word was our bond. A handshake and a look in the eye sealed the deals.

Our stock was pre-sold so the factories knew their future orders were assured. One owner said that 80% of his work was now with Galpharm but we needed even more products from him so I helped him to buy another factory so he could increase his production.

Our investment into India and the quality of the products they produced was the bedrock of Galpharm becoming number one, envied by all our competitors.

Most companies with medicinal licences in the UK manufactured products at their own factories.

We didn’t have a single factory of our own yet were taking the market by storm and by the time Galpharm was sold in 2008 we had 27 pharmaceutical licences manufacturing at seven different factories.

Our product range was impressive including painkillers, children’s medicines, cough and cold remedies, treatments for upset stomachs as well as foot, skin and eye care.

On average, every person in the UK was buying two to three packs of Galpharm medicines every year and eventually we were producing, packaging and distributing more than 75 million paracetamol tablets a month and had a 70% share of the UK’s affordable medicines market.

We’d changed everything … forever.